What have we built over the years? Here are just a few of our projects. Select a category in the menu below to view samples of our work. Click on any image for a magnified view.

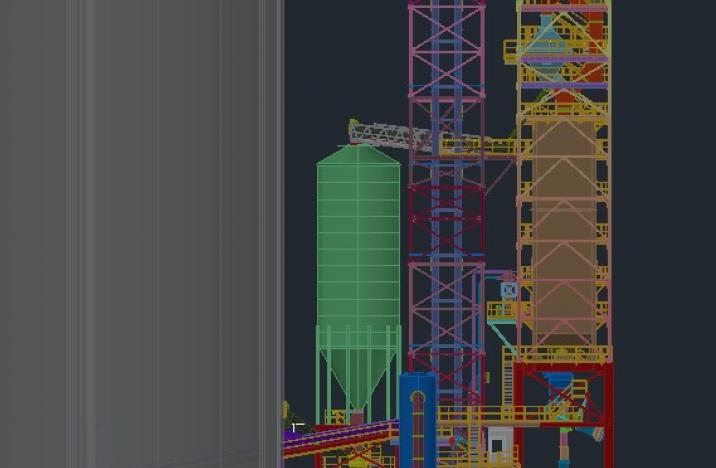

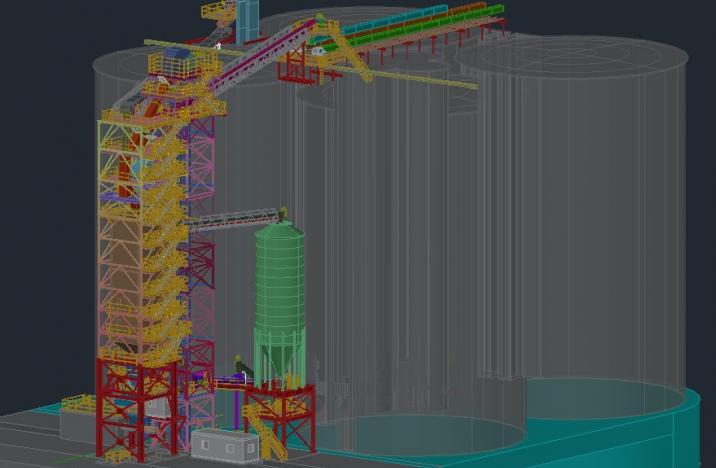

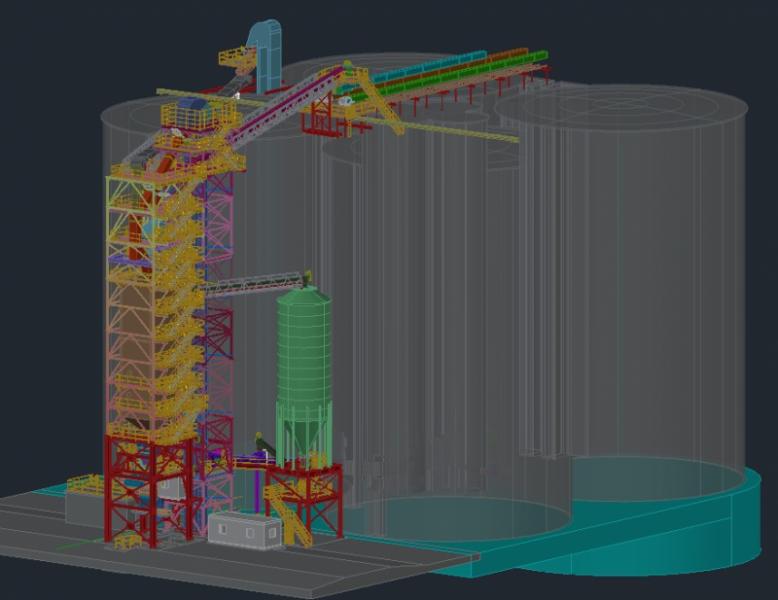

ESI provided and installed (49) BS&B explosion suppression and isolation cannons and (13) Triplex Explosion Pressure sensors at this major Ohio grain terminal facility.

The explosion suppression cannon modules propel an extinguishing agent into the developing fireball of an explosion. After an explosion has been successfully contained by discharge of the cannon modules, they can be refitted on-site. Components necessary for refit can be kept on-site without the need for special licensing for storage or handling. The original cannon and sensor modules can be refurbished, avoiding the need for a complete exchange of hardware. This capability significantly reduces the cost of ownership of the BS&B IPD explosion suppression system.