What have we built over the years? Here are just a few of our projects. Select a category in the menu below to view samples of our work. Click on any image for a magnified view.

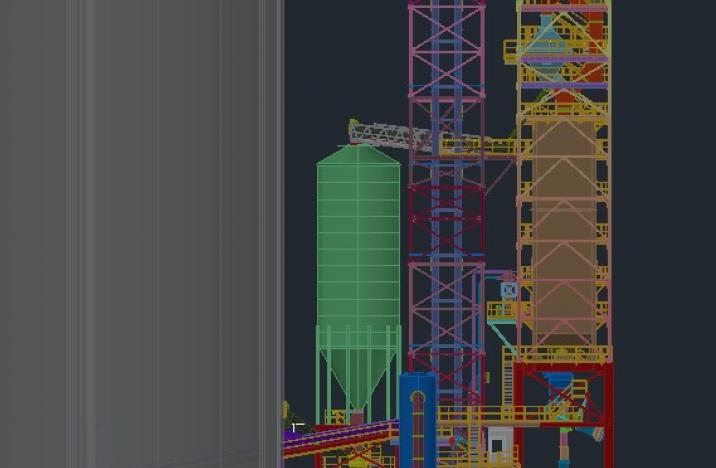

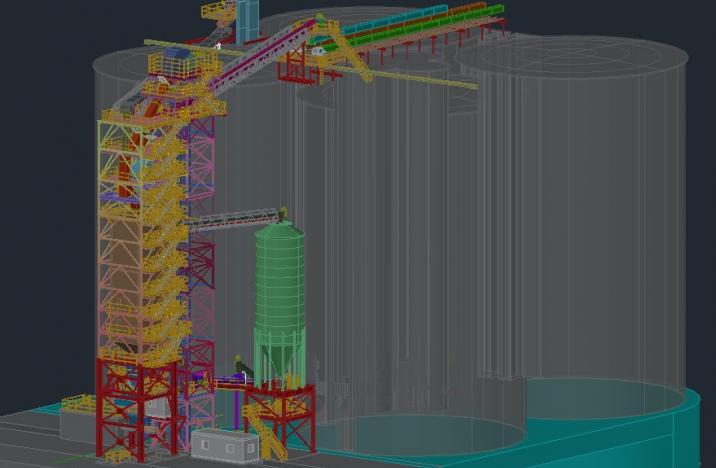

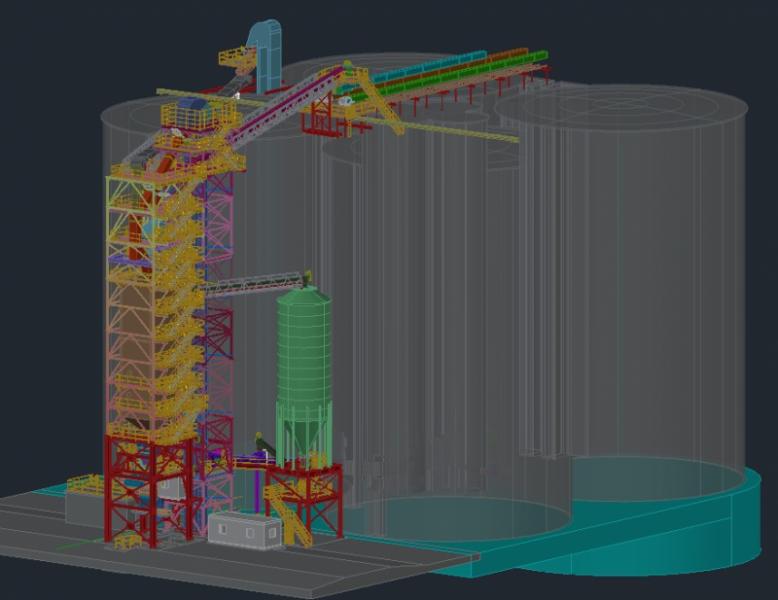

ESI leveraged our turnkey in-house resources to design, fabricate and install this major rail loadout expansion consisting of the following key elements: 80,000 BPH Compuweigh bulkweigher scale, galvanized support towers, 50,000 BPH Schlagel bucket elevator, 40,000 BPH Intersystems gravity screener, 10,000 bushel Sukup screenings bin, 15,000 CFM dust collection system, 15,000 BPH rail receiving pit, a 50,000 BPH Hi-Roller enclosed belt conveyor and a 15,000 BPH Hawthorne-Seving drag conveyor.